Glass Fabrication Machine

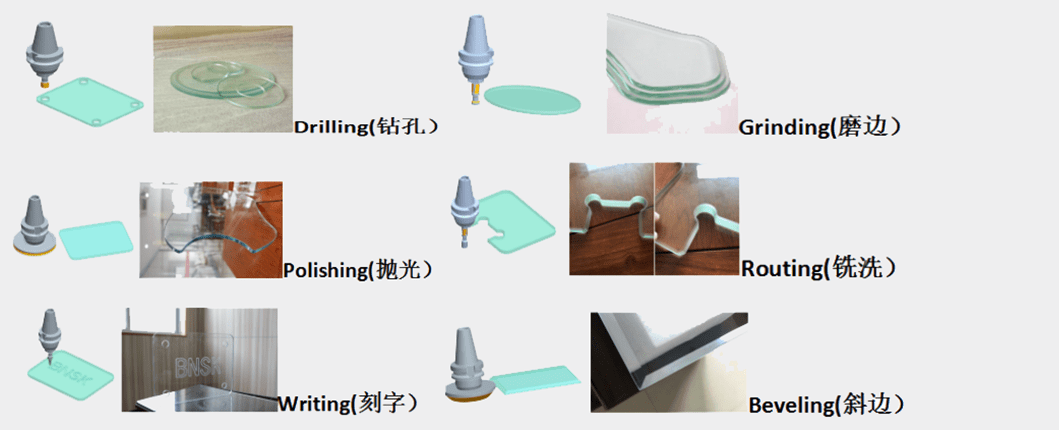

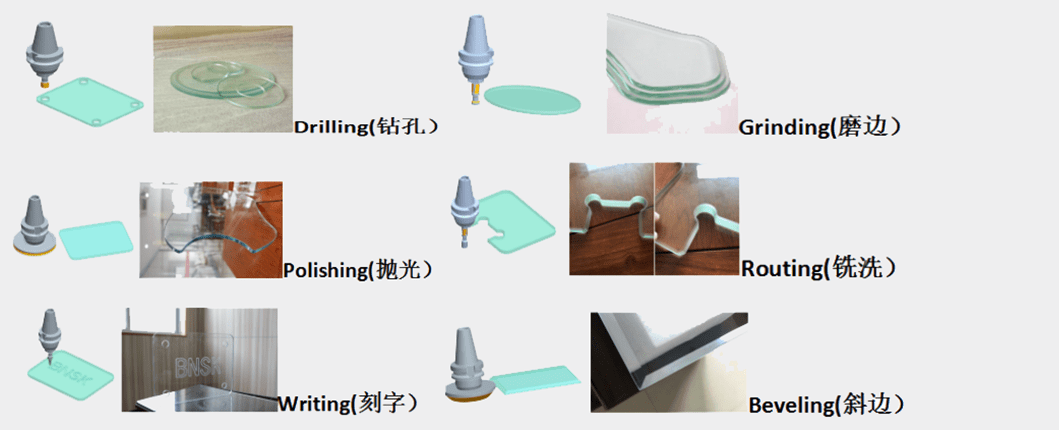

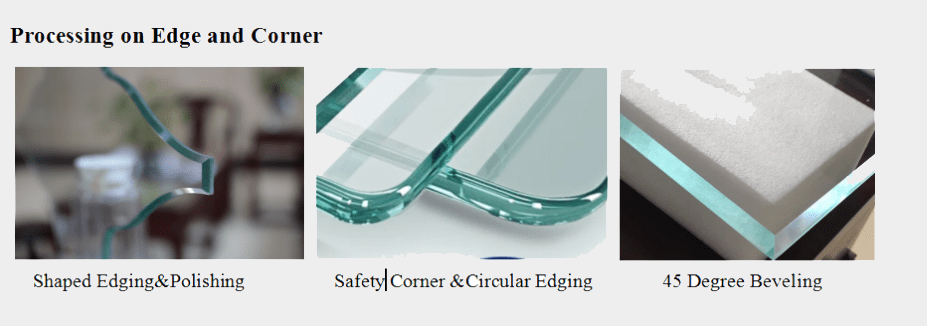

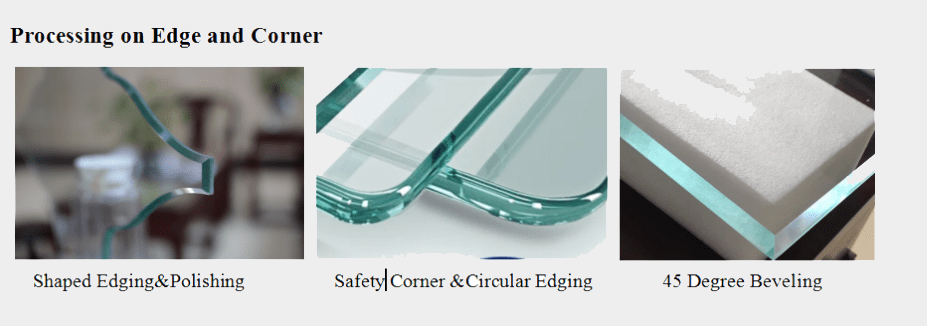

Glass fabrication machine is a high-performance, multifunctional system engineered to meet the diverse demands of today’s glass industry. Combining cutting, drilling, milling, beveling, and polishing in one unit, it leverages advanced CNC technology and precision-engineered components to ensure efficient, accurate, and reliable processing.

Key Features

- Versatile Functionality

Capable of performing cutting, drilling, milling, beveling, and polishing, this all-in-one machine streamlines multiple glass processing tasks, significantly boosting productivity. - High-Precision Performance

Outfitted with a high-accuracy CNC system and premium tools, the machine delivers consistently precise results, meeting the strict demands of advanced glass applications. - Advanced Automation

The latest automated control system enables one-click operation, intelligent path optimization, and smooth workflow management for increased efficiency. - User-Friendly Interface

An intuitive touchscreen interface enhances user experience, allowing for easy monitoring, quick adjustments, and improved operational control. - Durability & Reliability

Constructed with high-quality components, the machine is built for long-term use, ensuring stable performance even under continuous, high-load conditions. - Enhanced Safety Features

Includes multiple built-in safety measures such as a laser protective cover and emergency stop button to guarantee safe and secure operation.

Technical Specifications

- Maximum Processing Size: 3000mm x 1500mm

- Processing Thickness: 3mm – 25mm

- Spindle Power: 9kW

- Processing Speed: 0 – 12 meters/minute

- Positioning Accuracy: ±0.02mm

- Control System: CNC numerical control system

- Cooling System: Water cooling

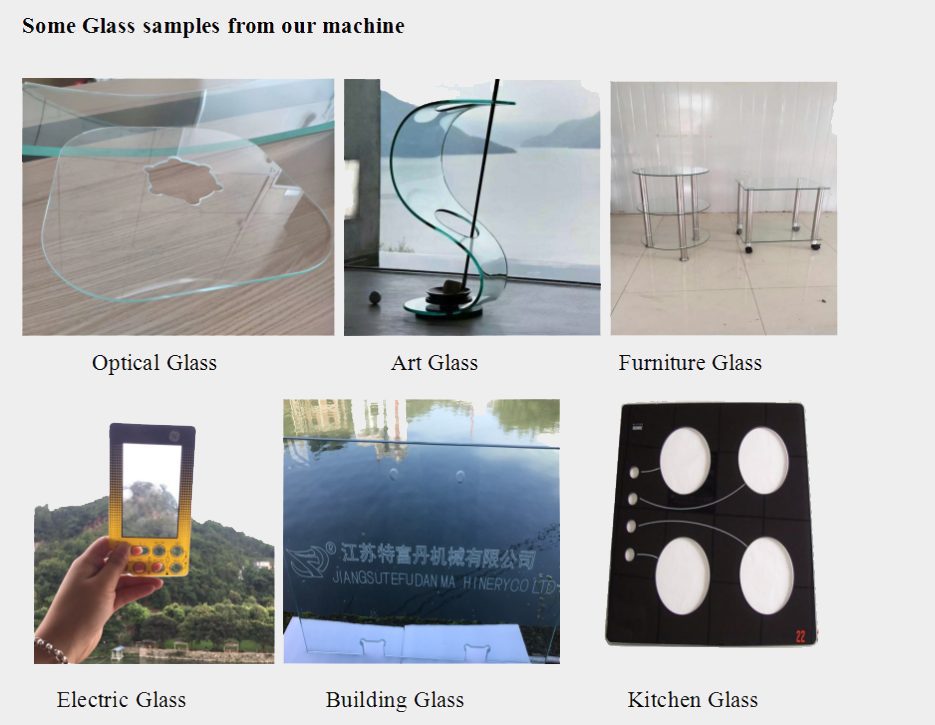

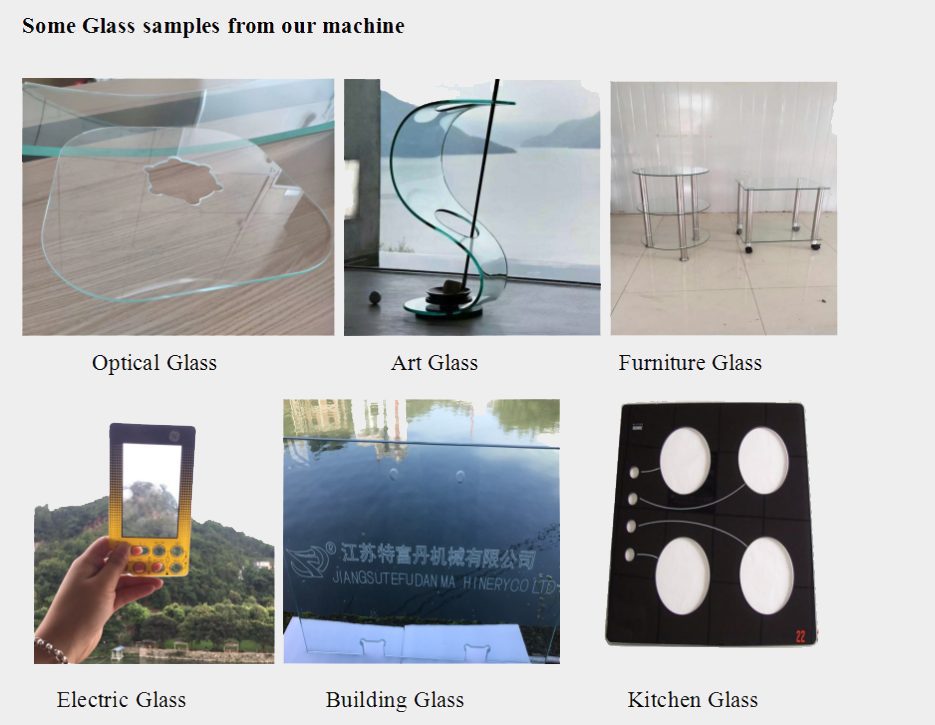

Application Fields

- Architectural Glass

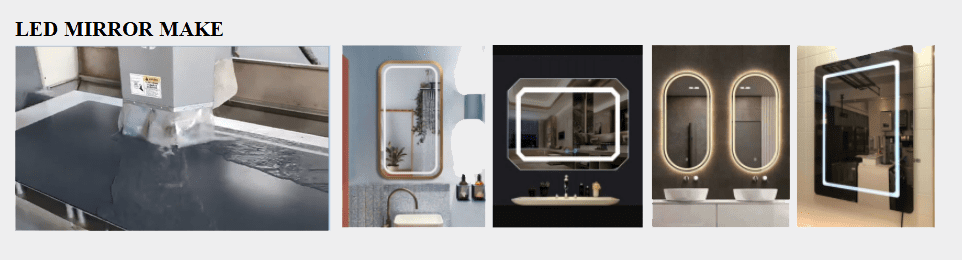

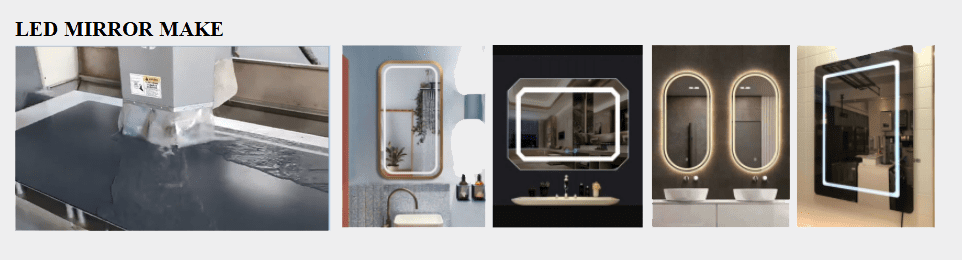

Ideal for precise processing of curtain walls, partitions, windows, and other structural glass used in modern architectural projects. - Decorative & Fancy Glass

Perfect for customized processing of mirrors, decorative panels, and interior glass elements used in homes, buildings, and design applications. - Industrial Glass

Enables accurate fabrication of glass components used in electronics, instrumentation, and other industrial sectors, ensuring consistent quality and precision.

Delivery & Service

We offer comprehensive pre-sales consultation and reliable after-sales support to assist customers throughout the entire process. Whether you're facing installation issues or operational questions, our services include:

Equipment installation guidance

Detailed user manuals

On-site supervision

Professional technical assistance

Our team is here to ensure smooth setup and optimal performance of your machine.

Why Choose Our Glass Fabrication Machine?

If you're looking for an effective, precise, and durable solution for your glass processing needs, our Glass Fabrication Machine is the ideal choice. Designed for versatility and efficiency, it helps solve complex fabrication challenges while accelerating your business growth.

Configuration Details

- CNC System & Wireless Remote

Equipped with a TAIWAN SYNTEC CNC system and wireless handle remote for accurate control and convenient operation. - Actuator, Transducer & Servo Motor

Utilizes TAIWAN SYNTEC components to ensure smooth motion control and reliable, high-precision performance. - Electrical Equipment

Features premium electrical components from GERMANY Schneider for enhanced operational safety and long-term reliability. - Ball Screw & Linear Guide

Fitted with high-precision TPI or HIWIN ball screws and linear guides for smooth, stable, and accurate motion control. - Electric Spindle

Includes a centrally water-cooled electric spindle, ideal for drilling, milling, and notching, while extending tool life and maintaining optimal temperatures during high-load operations.

Technical Parameter

| MODEL NO. | BN-T2412 | BN-T2416 | BN-T2620 | BN-T3016 | BN-T3020 | BN-T3720 |

| Stroke of X.Y.Z-Axis | 2400*1200*200mm | 2500*1700*200mm | 2600*2000*200mm | 3000*1600*200mm | 3000*2000*200mm | 3700*2000*200mm |

| Speed of X.Y-Axis | 10-20(m/min) | 10-20(m/min) | 10-20(m/min) | 10-20(m/min) | 10-20(m/min) | 10-20(m/min) |

| Speed of Z-Axis | 15(m/min) | 15(m/min) | 15(m/min) | 15(m/min) | 15(m/min) | 15(m/min) |

| Max Size of Glass | 2400*1200(mm) | 2400*1600mm | 2600*2000(mm) | 3000*1600(mm) | 3000*2000(mm) | 3700*2000(mm) |

| Min Size of Glass | 200*200 (mm) | 200*100 (mm) | 200*200 (mm) | 200*200 (mm) | 200*200 (mm) | 200*200(mm) |

| Glass Thickness | 1-40 (mm) | 1-40 (mm) | 1-40 (mm) | 1-40 (mm) | 1-40 (mm) | 1-40(mm) |

| Tool Library(PCS) | 1*4 | 2*4 | 2*5 | 2*4 | 2*5 | 2*5 |

| Spindle Speed | 0-12000(r/min) | 0-12000(r/min) | 0-12000(r/min) | 0-12000(r/min) | 0-12000(r/min) | 0-12000(r/min) |

| Spindle Power | 7.5-11(kw) | 7.5-11(kw) | 7.5-11(kw) | 7.5-11(kw) | 7.5-11(kw) | 7.5-11(kw) |

| Total Power of Machine | 17-21kw | 17-21kw | 17-21kw | 17-21kw | 17-21kw | 17-21kw |

| Voltage | 380V | 380V | 380V | 380V | 380V | 380V |

| Internal Water Consumption | 3 L/min | 3 L/min | 3 L/min | 3 L/min | 3 L/min | 3 L/min |

| External Water Consumption | 100 L/min | 100 L/min | 100 L/min | 100 L/min | 100 L/min | 100 L/min |

| 空气压缩Air Compression | 0.75MPA | 0.75MPA | 0.75MPA | 0.75MPA | 0.75MPA | 0.75MPA |

| Weight | 4800kg | 5000kg | 6000kg | 6000kg | 6500kg | 8100kg |

| Shipment Size | 5000*2300*2300(mm) | 4700*2300*2300mm | 5200*2300*2300(mm) | 5600*2300*2300(mm) | 5600*2300*2300(mm) | 6300*2300*2300(mm) |