CNC Vertical Glass Drilling and Milling Machine

Combining advanced technology with precision engineering, the baineng CNC vertical glass drilling and milling machine is designed to perform complex drilling and milling tasks with exceptional accuracy and efficiency. This high-performance machine delivers premium processing quality, enabling users to achieve professional results with a minimal investment in CNC equipment.

Key Features

- Advanced Numerical Control System

Equipped with a sophisticated CNC control system, the machine allows precise management of each axis and accurate speed regulation. This ensures consistent shaping quality and reliable performance, whether handling simple patterns or complex glass designs. - High-Efficiency Drilling & Milling

Optimized for processing large flat glass, the machine executes intricate drilling and milling operations automatically. Once the glass is loaded onto the feeding rack, it carries out all programmed tasks efficiently, ensuring excellent productivity with minimal manual intervention. - Versatile & Adaptive Control

The flexible control system adapts to the specifications of different glass products, completing all tasks autonomously. Ideal for structural applications such as frameless doors and curtain wall panels, it seamlessly integrates drilling and milling functions in a single setup. - Space-Saving Vertical Design

The compact vertical structure allows for easy loading and unloading, while minimizing the machine’s footprint. Protective covers over key components enhance safety and reduce workspace obstructions. Additionally, the vertical layout supports an efficient and cleaner coolant water system.

Technical Specifications

- Maximum Processing Size: 3000mm x 1500mm

- Processing Thickness: 3mm – 25mm

- Spindle Power: 7.5kW

- Processing Speed: 0 – 12 meters/minute

- Positioning Accuracy: ±0.02mm

- Control System: CNC numerical control system

- Cooling System: Water cooling

CNC vertical glass drilling and milling machine offers precise, high-speed processing for architectural, decorative, and industrial glass. Featuring automated control, space-saving design, and user-friendly software, it ensures efficiency, accuracy, and long-term durability.

Applications of CNC Vertical Glass Drilling

- Architectural Glass

Ideal for precise and efficient processing of glass used in curtain walls, partitions, windows, and other structural applications. Delivers consistent results for modern architectural demands. - Decorative (Fancy) Glass

Perfect for customized engraving, drilling, and marking on mirrors, decorative panels, and glass elements used in home interiors and artistic designs. - Industrial Glass

Enables high-precision machining of glass used in electronics, instrumentation, and other industrial applications—ensuring durability and performance standards are met.

Delivery and Service

We provide comprehensive pre-sales consultation and responsive after-sales support to guide customers through every stage of ownership. Our services include:

Professional guidance for equipment selection

Detailed operation manuals

On-site or remote installation supervision

Ongoing technical support for optimal performance

If you’re searching for the best CNC vertical glass drilling and milling machine, our solution stands out for its efficiency, accuracy, and long-term reliability. It’s designed to solve production challenges and accelerate your business growth.

BAINENG Software

Developed in-house by our IT team, BAINENG Software simplifies the entire processing workflow. It includes a library of common patterns and allows users to input parameters for automatic toolpath generation. The software is user-friendly and environmentally conscious.

File Compatibility: Easily import CAD2000 .dxf files into BAINENG Software to automatically generate required machining codes.

Operation Process with BAINENG Software

Import File – Load your CAD file

Select Lines – Choose the paths you want to process

Set Parameters – Define depth, diameter, and other specifics

Update Parameters – Adjust settings as needed

Generate Code – Create the processing code automatically

Installation and Functionality

- BAINENG CAM Software

Compatible with Windows systems, this software allows users to draw shapes in CAD and auto-generate machining codes in CAM, streamlining the production process. - Proprietary MARCO Software

Designed for frequent applications like shower doors, overhang doors, and floor hinges. Users simply input required dimensions without the need for full CAD drawings. - Scanning Code Recognition

An efficient solution for small batch orders, enabling quick and accurate processing with minimal manual input.

Production Applications

This machine is optimized for mass production of:

Frameless shower doors

Sliding doors

Glass curtain walls

And other precision-based glass structures

It significantly reduces labor time and production costs, making it a cost-effective and highly productive solution for modern glass processing.

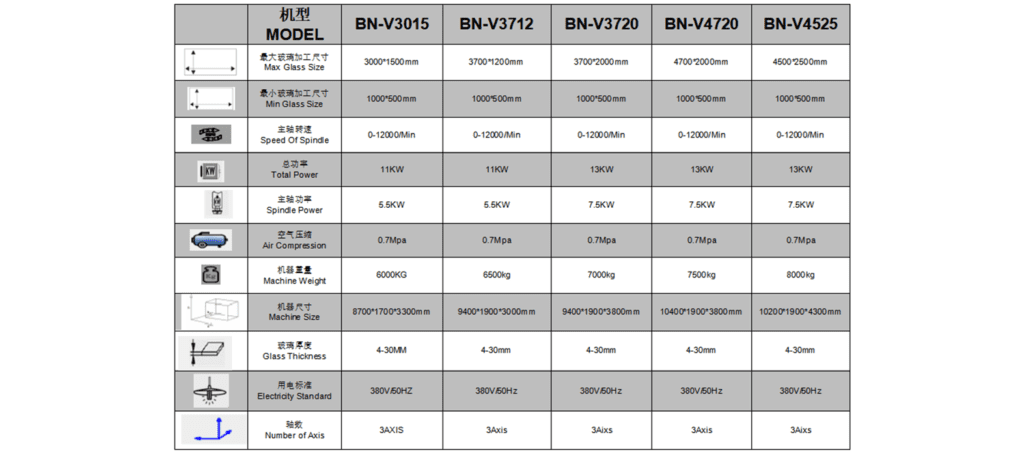

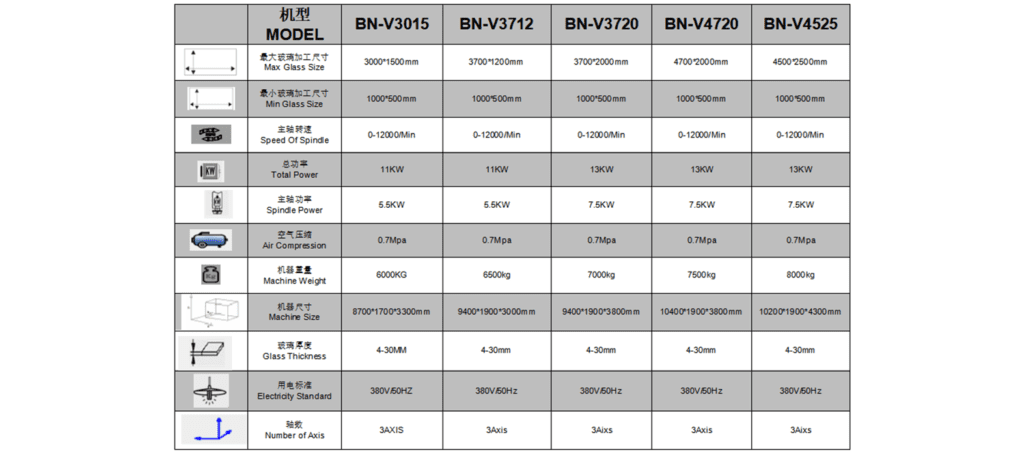

Technical Parameter

| Description | Brand | Made in |

| Linear Guide | Hiwin | Taiwan |

| Ball Screw | HIWIN/TPI | Taiwan |

| Servo Motor | Mitsubishi/Syntec | Japan/Taiwan |

| Bearing | NSK | Japan |

| Sliding Block | Hiwin | Taiwan |

| Control System | Syntec | Taiwan |

| Control Electrical | SCHNEIDER | France |

| Image Converter Software | BAINENG | China |

| Spindle | Baineng | China |

| Synchronous Belt | / | China |

| Air Cylinder | Airtac | Taiwan |

| Synchronous Wheel | / | China |

| Water Pump | / | China |

| Steel Plate | Baosteel | China |

| Protection Cover | / | China |

| Description | Quantity | Remark |

| Gloves | 1pair | / |

| Adjustable cushion | 4pcs | / |

| X axis synchronous belt | 1pcs | / |

| Toolbox | 1box | / |

| Adjustable wrench | 1pcs | 250*30(mm) |

| Allen wrench | 9pcs | S1.5 S2.0 S3.0 S4.0 S5.0 S6.0 S8.0 S10.0 S.12 |

| Inner Allen screw | Some pcs | M6*10,M6*20 |

| Allen Nut | Some pcs | M10*20,M6*10,M6… |

| Thread seal tape | 1pcs | / |

| Water Pump | 1set | / |

| Transformer | 1set | / |

| Spindle water cooled machine | 1set | / |

| 3functions in one tool | 3pcs | Including milling, drilling, chamfering |