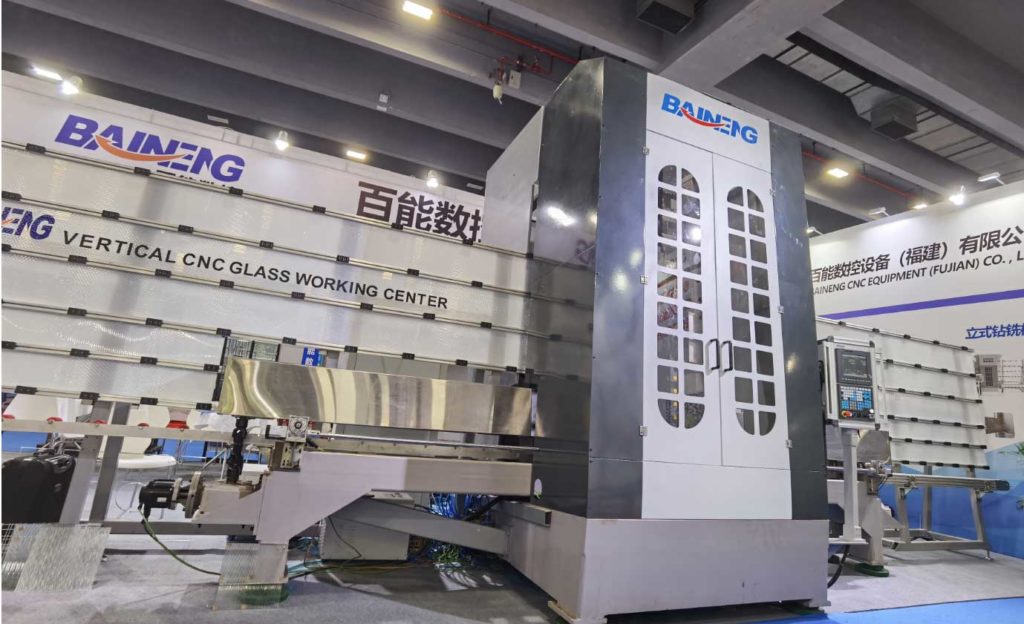

CNC Glass Vertical Working Center

Baineng CNC glass vertical working center is an advanced solution engineered for high precision, efficient performance, fast processing speeds, and user-friendly operation. Designed to handle complex glass tasks with ease, it excels at edging, drilling, notching, cutouts, and polishing—making it the go-to choice for mass production in industries such as frameless shower doors and glass curtain walls.

Key Features

- Latest Numerical Control System

Equipped with an advanced numerical control system that ensures high efficiency, smooth operation, and precise performance—meeting customer demands for accuracy and top-quality glass processing. - User-Friendly Software

The intelligent software features an intuitive interface with built-in layout templates and automatic path generation. Designed for ease of use, it streamlines the operation process and reduces setup time. - Powerful 5-Axis Structure

Built with a robust 5-axis system, the machine performs inside and outside edging, drilling, milling, notching, and polishing—all in a single cycle. It includes dual spindle heads and a water-cooled electric spindle, delivering 7.5kW of power and speeds up to 12,000 rpm for enhanced precision and productivity. - Compact Vertical Design

The space-saving vertical layout minimizes floor space usage while allowing easy loading and unloading of glass sheets. Ideal for high-output production environments. - Multi-Function Capability

Supports a wide range of functions including: Inside/Outside Edging, Drilling, Milling, Cutting / Shape Cutting, Chamfering, Polishing

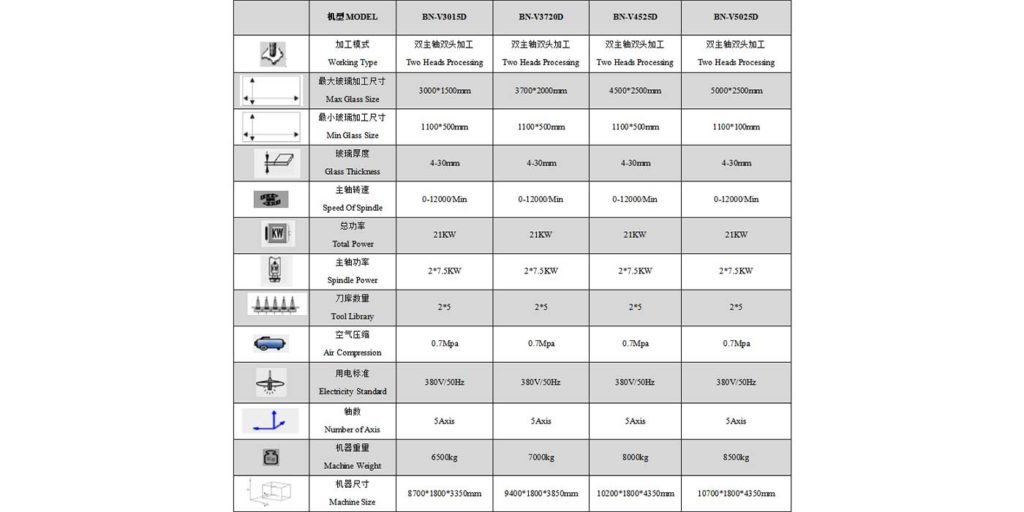

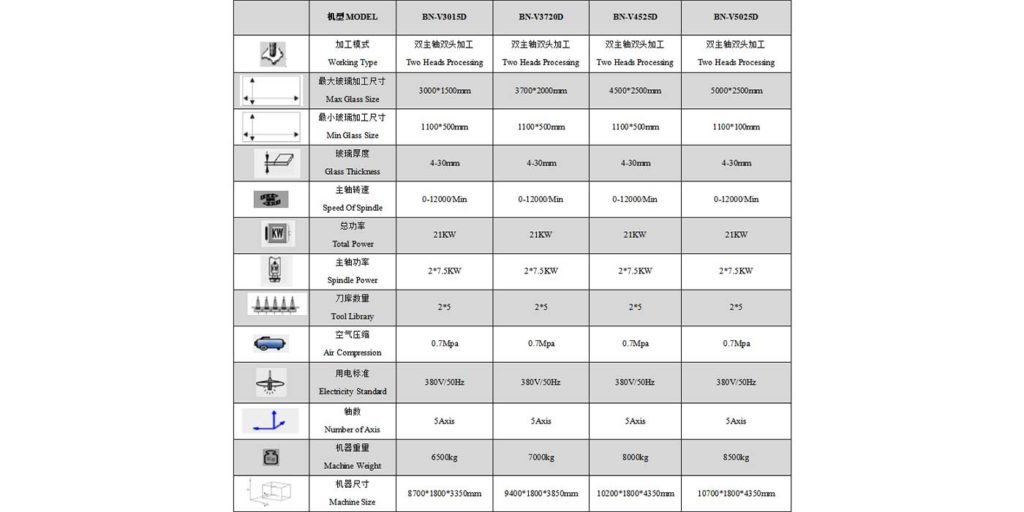

Technical Specifications

- Maximum Processing Size: 3000mm x 1500mm

- Processing Thickness: 3mm – 25mm

- Spindle Power: 9kW

- Processing Speed: 0 – 12 meters/minute

- Positioning Accuracy: ±0.02mm

- Control System: CNC numerical control system

- Cooling System: Water cooling

CNC glass vertical working center delivers high-precision drilling, milling, and engraving for flat glass. With its vertical design, advanced control system, and intelligent software, it ensures efficient processing, space-saving operation, and reliable performance for various glass applications.

Baineng VERTICAL GLASS WORKING CENTER MACHINE

This state-of-the-art vertical glass processing machine integrates cutting, milling, drilling, and polishing capabilities into one powerful system. Built with the latest CNC technology and precision-engineered mechanical components, it ensures consistent, accurate results across a wide range of glass types and thicknesses. Whether you’re producing structural panels or intricate decorative elements, the Baineng CNC Glass Vertical Working Center delivers unmatched productivity and processing quality—making it a smart investment for the modern glass industry.

Advantages

Advanced Numerical Control System

The machine is equipped with the latest numerical control system, ensuring high efficiency and ease of operation. It meets customer expectations for processing accuracy and superior quality output.Smart and User-Friendly Software

Developed by experienced engineers, the integrated software includes a library of common layout templates. By simply entering parameters, the system automatically generates the most efficient processing routes—streamlining operation and saving time.Robust 5-Axis Construction

This machine features a powerful 5-axis configuration capable of performing inside/outside edging, drilling, milling, notching, and polishing in a single cycle. It’s equipped with two spindle heads and a water-cooled electric spindle that delivers up to 7.5kW of output power and a maximum speed of 12,000 rpm—greatly improving efficiency while maintaining exceptional precision.Compact Vertical Design

The vertical structure saves valuable floor space, making it easier to load and unload glass sheets—ideal for high-throughput production environments.Multi-Functional Capabilities

Supports a wide range of functions including: Inside/Outside Edging, Drilling, Milling, Cutting / Shape Cutting, Chamfering, Polishing

Applications of CNC Glass Vertical Working Center

This machine is perfectly suited for processing frameless shower doors, sliding doors, glass curtain walls, and more. It’s the ideal solution for reducing labor and material costs while significantly improving production efficiency—making it a smart investment for modern glass manufacturers.

Preparation for Installation and Training:

- Prepare 8 steel plates (300x300x5mm) for machine bearing feet.

- Supply compressed air at 0.7-0.8MPA or provide an air compressor.

- Use 10mm diameter air pipes (length according to installation space).

- Power Circuit: 36² & 24² (length as per installation space).

- Independent power control circuit breaker (3P45A).

- A 10-20 ton jack lifting (to adjust machine level).

- Use Windows 7 (32-bit) computer.

Application Fields

- Architectural Glass

Ideal for precise processing of glass used in curtain walls, windows, partitions, and other structural architectural elements. Ensures reliable performance and high-quality finishes for modern construction needs. - Decorative (Fancy) Glass

Perfect for custom engraving, cutting, and finishing of mirrors, interior glass elements, and artistic glass used in home décor and architectural features—enhancing aesthetic appeal and uniqueness. - Industrial Glass

Engineered to meet the precision demands of glass used in electronics, instrumentation, and other industrial applications. Delivers consistent accuracy and durability for high-performance environments.

Delivery and Service:

We offer comprehensive pre-sales and after-sales support, including equipment selection guidance, detailed operation manuals, installation supervision, and ongoing technical assistance—ensuring you have everything you need for smooth and successful operation.

If you're in search of a reliable and high-performance solution, our CNC Glass Vertical Working Center is the ideal choice. Engineered for precision, efficiency, and long-term durability, it delivers outstanding results across all glass processing tasks. Invest with confidence—your satisfaction is guaranteed.Technical Parameter

| Description | Brand | Made in |

| Linear Guide | Hiwin | Taiwan |

| Ball Screw | HIWIN/TPI | Taiwan |

| Servo Motor | Mitsubishi | Japan |

| Bearing | NSK | Japan |

| Control System | Syntec | Taiwan |

| Control Electrical | SCHNEIDER | France |

| Image Converter Software | BAINENG | China |

| Description | Quantity | Remark |

| Gloves | 1pair | / |

| Adjustable cushion | 4pcs | / |

| X axis synchronous belt | 1pcs | / |

| Toolbox | 1box | / |

| Adjustable wrench | 1pcs | 250*30(mm) |

| Allen wrench | 9pcs | S1.5 S2.0 S3.0 S4.0 S5.0 S6.0 S8.0 S10.0 S.12 |

| Inner Allen screw | some pieces | M6*10,M6*20 |

| Thread seal tap | 1pcs | / |

| 3functions in one tool | 3pcs | / |